Reverse Engineering

Do you have a physical PCB assembly that you want to manufacture more of but you don’t have the necessary data files required for manufacturing? Well, there is a solution and we can help you.

We see this quite a lot. Customers send us a sample board and from it, we reverse engineer new CAD files containing Schematics, PCB layout, Parts Lists and finally Gerber and Drill data. All the data needed to manufacture new circuits.

If due to the age of the product, we find that some of the components are obsolete we will find alternatives. As we are now in control of the design files, any changes, such as component substitutions, are easily implemented in a professional way. The board is up-issued and the dataset integrity is maintained for future modification or production.

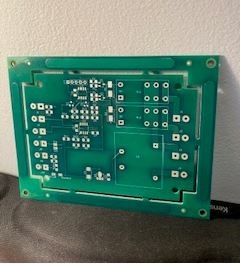

The image below shows an example of a PCB supplied to us and on this occasion, our customer also included a Parts list. We had no other data to work with.

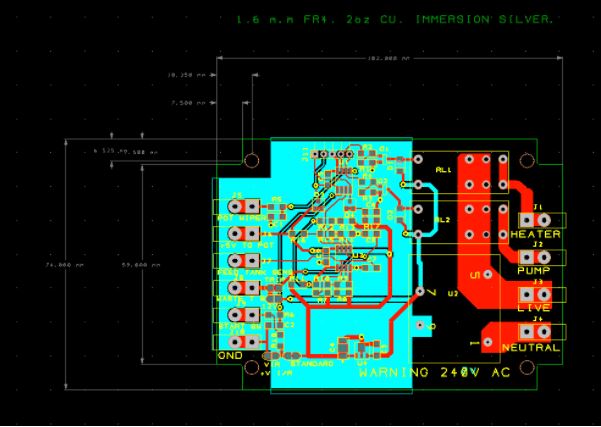

The circuit was reverse engineered as a “Project File”. This means that every file required for the manufacturing, procurement of components, assembly and finally even schematics (should you be seeking market approvals) were recreated. The whole product makeup now resides in just one single dataset.

Image 2. Shows the reverse engineered CAD image for the updated circuit produced using the techniques set out above.